Published on November 17, 2023 by Ankur Arora

According to the International Energy Agency (IEA), 10.3m electric vehicles (EVs) were sold in 2022, compared to 3.0m in 2020 – an almost fourfold increase in just two years. EV sales accounted for only 4% of the global car market in 2020, but the share was c.14% in 2022. The EV market is growing exponentially, driving demand, due to government policies, financial incentives or subsidies and high oil prices.8

The IEA forecasts that EVs could constitute c.30% of global car sales by 2030. Although increasing demand for electric mobility is good news for the climate, it threatens the ecosystem and poses challenges for ESG due to the lithium extraction required and related social factors.2

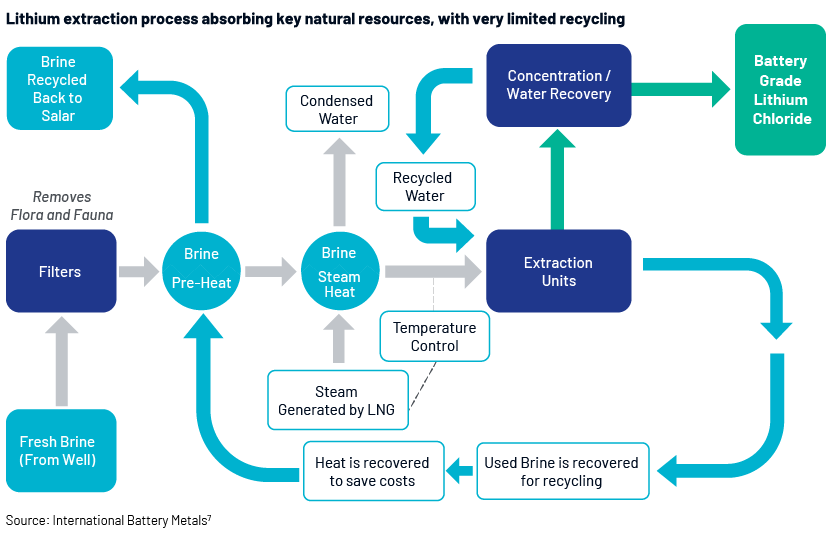

What is the lithium extraction process?

The conventional process of extracting battery-level lithium from brine water requires selective absorbent. In the first stage of extraction, a solution containing lithium is extracted from brine water, and the solution is then cleaned to remove impurities. It subsequently undergoes multiple processes involving water to generate high-grade lithium carbonate and lithium hydroxide.7

Lithium and battery supply chain is difficult to sustain

A key challenge is the use of raw resources including natural materials for the production of EV batteries; such resources are mostly available in countries where ESG compliance and norms are very weak. This trade-off between electric mobility and ESG-related malpractice has raised concern about sustainability among clean-tech companies, manufacturers of EVs and EV components, and ESG-focused investors.2

Another challenge is the difficulty in obtaining lithium, copper and nickel due to the large global demand for EV products.3

Demand for lithium-ion batteries for light vehicles is likely to reach c.3.4 Terawatt hours (TWh) annually by 2030, according to S&P Global Mobility forecasts. The auto sector’s output was just 0.29 TWh in 2021. The only strategic cost approach is sourcing EV batteries locally. If this is insufficient to meet demand, it would require sourcing from countries that are rich in natural resources but are facing political upheaval or are known for anti-social practices including child labour and other forms of exploitation.

Peru and Chile, which control 40% of the world's copper, face political turmoil and trade-union protests against the government over rights and compensation.3

Other examples of challenging the ESG ecosystem are Chile’s government commissioning a USD2.5bn mining project that would threaten a rare species of penguin, and child labour commonly found in cobalt mines in the Democratic Republic of Congo.3

Metal extraction is reducing water resources, specifically of poor nations

The production of one ton of industry-level lithium requires 2.2m liters of raw water, putting substantial pressure on our planet’s ecosystem

Lithium extraction consumes a substantial amount of water. South America's lithium triangle (Bolivia, Chile and Argentina) is home to more than 50% the world's known lithium resources, but the significant use of water for extraction is compromising the environment; this is in addition to the political and economic turmoil the region faces.4 Local communities (in addition to plants and animals) are affected as already-scarce water supply is pressured by increased mining activity.

Unlike in Australia, where lithium is extracted from hard rock, it is extracted from salt flats in South America. Saltwater contains a number of minerals and metals and is processed using evaporation. Thus, heavy water consumption significantly pressures the ecosystem by reducing sources of groundwater and making the area prone to drought.4

Companies extracting lithium from Chile’s Salar de Atacama have already used up 65% of the region’s water supply, causing an extreme water shortage that is affecting agriculture and the maintenance of livestock.5

Despite disrupting the ecosystem, EV battery production still does not meet global demand

Due to mismanaged lithium extraction in the nations listed above, battery production is not up to the levels required. Facing multiple global logistics issues due to the Russia-Ukraine war, Brexit, the pandemic and other challenges, General Motors has delayed production of its EV vehicles. It is now pushing production of 400,000 EVs to 1H 2024. Volkswagen has also announced delaying some of its EV production – its much-hyped EV project Trinity has been delayed from 2026 to 2030, and it plans to put construction of its new battery plant in Europe on hold.1

The world has sufficient nickel and lithium, excluding lithium supply from Russia, to manufacture 14m EVs in 2023, according to European clean transport campaign group Transport & Environment (T&E).1

How to mitigate the issues

1. Prioritise supply-chain security, transparency and resilience: In a usual business proposition, investors and consumers are more focused on the end product than on the entire value chain. This is what is happening in the case of EV manufacturing as well, with little focus on the lithium extraction process. For the purpose of sustainability, all stakeholders should pay attention to each stage of the EV manufacturing process – from extraction and assembly to final sale of the vehicle – and the adoption of innovative tech support and solutions for reusing and recycling materials and resources should be encouraged.6

2. Transform and upskill workforce: The paradigm shift from traditional energy options to renewable energy and the concept of net zero emissions present significant opportunities to enhance employee skillsets.6

The time to enhance skillsets is now. Companies that comply with ESG norms and ethics have a higher likelihood of employing the best workers, as workers are now looking for companies with higher values.6

3. Ensure transparency, cooperation, reform and data organisation: Due to the lack of regulation and reforms, there is a constant and increasing threat to the environment; however, this could be mitigated by taking small but significant steps. For instance, the Atacama People’s Council (Chile) plans to monitor water levels of certain lakes, so it can take timely action. There is scope for further development, for example, to monitor lithium generation. It is also necessary to track how other aspects of zero carbon emissions do not impact the environment, animals and humans. Such practices need to be implemented worldwide, not only to track depletion of water resources, but other aspects of the ecosystem as well.5

Conclusion

Global demand for EVs in increasing, and strong supply chains, skilled workforces and substantial investments play a pivotal role in meeting this demand. The poorer nations are the most compromised in the effort to make the system carbon-free. Hence, corporations, governments and ESG bodies should collaborate to identify innovative and more sustainable approaches to protect the ecosystem.

How Acuity Knowledge Partners can help

We help consultants and corporations achieve ESG goals across the business lifecycle, offering a wide spectrum of customised research across the sustainability/ESG lifecycle. Key products we offer include ESG analysis and programme development; transparency, ethics and socially responsible human resource management; measuring and monitoring goals, sustainable management and strategies; climate change solutions; and ESG reports.

References:

-

https://www.esginvestor.net/time-to-break-the-ev-bottleneck/

-

https://kleinmanenergy.upenn.edu/podcast/raw-materials-pose-esg-challenge-for-ev-industry/

-

https://www.ecogeneration.com.au/the-top-esg-trends-in-2023/

-

https://www.iea.org/energy-system/transport/electric-vehicles

Tags:

What's your view?

About the Author

Ankur has 11 years of experience in managing and executing projects across multiple sectors assisting clients in quantative and qualitative research areas within investment banking, consulting, private equity and restructuring groups. Ankur completed his PGDM from Kirloskar Group in Karnataka

Like the way we think?

Next time we post something new, we'll send it to your inbox