Published on September 2, 2021 by Jigyasa Arora

Digitalisation is gaining ground in all aspects of human life and has been expanding its footprint in factories as well. Digitalisation has the potential to go beyond automation, helping factories achieve “smart production”. It offers many benefits and efficiencies, but challenges as well. We present a 360° view of digital factories in this blog.

What are digital factories?

A digital factory uses different technologies to automatically share information/data digitally across people, machines and materials. These technologies link systems and processes across different areas of production to create an integrated approach to manufacturing. Some of these technologies are highlighted below:

|

Technology |

Introduction |

Application in factories |

|---|---|---|

|

Industrial internet of things (IIoT) |

Small sensors and other hardware connected to communicate with each other |

Asset management, energy reduction, etc. |

|

Big data |

Massive stores of information for analysis |

Customer, supplier and production analysis |

|

Artificial intelligence (AI) |

Leverages data to create machine-learning models |

Forecast demand, perform predictive and prescriptive maintenance on machines, etc. |

|

Automation |

Enables machines to perform tasks faster and more accurately than their human counterparts |

Start/stop machines and work 24 hours a day, without human intervention |

|

Humanoid robots |

Perform most of the tasks a human being performs but with minimal errors |

Can operate in dangerous environments, do not require breaks and can work around the clock |

|

Drones |

Flying robots fitted with sensors and GPS, remotely controlled through software |

Used for site audits, materials transportation, high-quality imagery of properties, etc. |

|

Virtual reality |

Computer-generated simulation used for interacting within an artificial 3D environment |

Helps simulate production process and assembly line configurations, assisting in identifying potentially dangerous situations |

|

3D printing |

Produces objects rapidly and at low costs |

Used in the aerospace and defence sectors to manufacture lightweight parts |

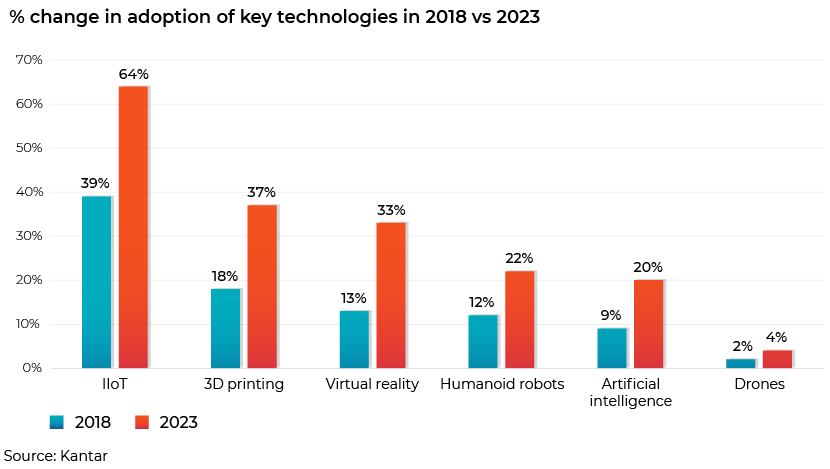

Growing adoption of key technologies

Investment in digital technologies will almost double over 2018-23, according to a survey conducted by Kantar, a market research and data analytics company. Hence, an industry/organisation should focus its strategy on investing in efficient technologies and initiating the process of conversion to digital factories. This can allow them to obtain first-mover advantage, achieve economies of scale, compete with crucial market players and achieve significant return on investment (ROI).

Benefits of digitalisation

There are many benefits of factory digitalisation, the main one being customer satisfaction. Constantly changing customer demands could be met in the shortest possible time when entire production processes are optimised by incorporating technologies such as automation, humanoid robots and drones. Other key benefits of digitalisation are highlighted below

-

Significantly reduces energy use: Tracking the energy use of each piece of equipment helps make significant process changes and save money on energy costs, boosting profit margins. Technologies adopted include IIoT, big data and AI.

-

Boosts efficiency: By removing inefficient human decision-making processes, factories can produce more in less time and with fewer material resources, malfunctions and scrap parts. Technologies adopted include humanoid robots and drones.

-

Reduces overall costs: Digitalisation could result in lower labour costs and direct costs, such as capex and logistics- and inventory-related costs. Technologies adopted include IIoT, big data, AI, automation, humanoid robots and drones.

-

Reduces production time: Connected systems, data-driven and strategic processes, and real-time tools and data points lead to less production time. Technologies adopted include automation, humanoid robots and drones.

-

Provides additional time for innovation: With digitalised systems and real-time analytics, factories have more room to experiment and find solutions to new problems and test ideas at scale without spending unnecessary resources. Technologies adopted include IIoT, big data and AI.

-

Increases ROI: A 2017-20 survey conducted by Kantar Emnid found that if a company invests in a digital factory and adopts most of the key technologies highlighted above, its ROI is likely to increase by 48% in four years, with an average increase in ROI of 11% in the first year, 12% in the second and 22% in the third.

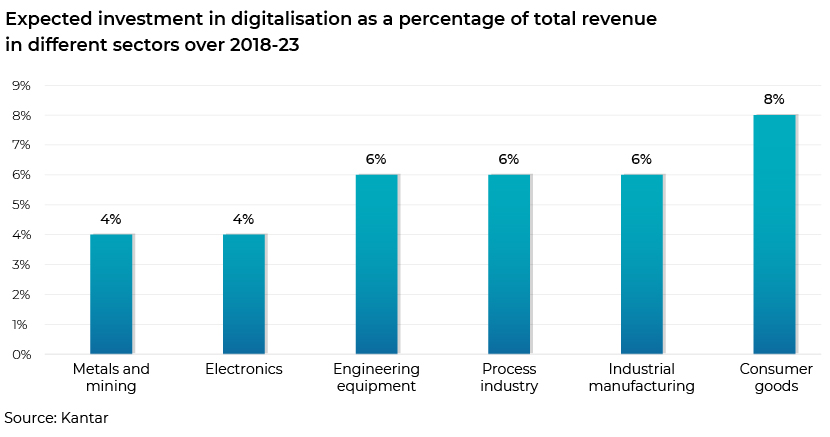

Investment in digitalisation has grown as more sectors realise its benefits. Several leading organisations, belonging to sectors such as electronics, industrial manufacturing and consumer goods, have invested in digital factories.

Organisations planning to convert to digital factories intend to invest, on average, 6% of their total annual revenue in digitalisation over the next five years, i.e., 1.2% per annum. Companies in the consumer goods sector are at the higher end of the scale (8%) and those in metals and mining are at the lower end (4%).

Challenges in factory digitalisation

The biggest challenge is doing away with traditional operations and being flexible in terms of funding initiatives to implement new technologies.

This requires detailed planning and substantial integration among processes, technology and labour. Each operation is considered a single unit for digitalisation and must be tested for smooth integration with existing processes until all the operations are digitalised and streamlined. Key challenges in the process include the following:

-

-

Lack of integrated strategic planning

-

Companies should consider a problem from perspectives such as strategy, product design and changes in mode of operation. They need to choose the right technology based on the actual situation and goals, rather than blindly pursuing cutting-edge technology, as this may affect other operations during the digitalisation process.

-

-

Technology not fully considered

-

Companies need to develop a technology roadmap based on their digital factory strategy and implement technology transformation initiatives. This would minimise implementation risks and any adverse impact on business and operations.

-

-

Implementation of technology

-

Once gaps are analysed and a specific technology chosen, there could be further gaps between requirements and mapping technology with existing processes. Failure to assess such gaps and align with existing processes could hamper “smart factory” implementation or lead to failure of the system during implementation.

-

-

ROI takes time

-

If a company plans to achieve a high degree of factory digitalisation or automation, it would take time to ensure all the technical aspects are in place. From a cost-benefit perspective, it may take a long time for the investment to yield a return. Companies should, therefore, think of efficiency not only in terms of ROI. Otherwise, they would hesitate to invest in digital factories.

-

-

Need for technical talent

-

A digital factory’s production and operation process is highly integrated, highlighting the need for technical talent. Single-field specialists need to be replaced by interdisciplinary specialists who would understand digital delivery across multiple businesses and operations. Companies would also need to invest in training existing staff to handle operations after digitalisation.

Key steps towards factory digitalisation

Digital transformation can be broken down into the following steps:

1. Gap assessment

2. Developing a strategy for digitalisation

3. Streamlining and optimising processes

4. Scaling up operations to take full advantage of digitalisation

We detail these key steps below:

-

-

Assess digital readiness

-

Understand an organisation’s current level of maturity by assessing factory floor and machines that can/cannot collect or transmit the data needed to support a digitalisation initiative. Lastly, identify how staff on the floor collect and use information.

-

-

Map strategy

-

Develop a digitalisation strategy to ensure the goals and objectives are aligned with the company’s vision. Maximum benefit would be derived if a technology fits the overall strategy and operating goals.

-

-

Define roadmap

-

Create a roadmap and timelines for achieving targets. Start small, as it is difficult to secure funding knowing that the economic benefits of digitalisation in the initial phase are not easy to calculate and an organisation often takes time to achieve a breakthrough. Pilot projects would help you assess the approach that works best for your company. Employees need to be given an important part to play in these pilot projects, as it would help them to adapt easily to the digital transformation.

-

-

Discover new businesses and revenue streams

-

Adopt real-time analytics, big data, etc. to experiment and test ideas at scale. When other organisations are learning from your growth, start investing in new businesses and explore other revenue streams to gain an advantage.

-

-

Be ready for and accept culture change

-

Transforming factories into digital factories requires a culture change organisation-wide – from the top to the bottom. Management must take the initiative to drive transformation while ensuring all pre-requisites with respect to culture change are met.

-

-

Implement, scale and optimise

-

Plan to benefit from digitalisation by achieving economies of scale in each revenue stream to minimise risks from competitors. Start investing in R&D to optimise operations and minimise fixed and operational costs.

How Acuity Knowledge Partners can help

As digital factories offer a range of benefits in various phases of consideration and implementations, it is imperative that manufacturing firms adopt them. Acuity Knowledge Partners has a strong team of subject-matter experts who can leverage their expertise to provide solutions for industries and companies that are looking to invest in digitalisation.

References

https://www.capgemini.com/wp-content/uploads/2019/11/Report-%E2%80%93-Smart-Factories.pdf

https://www.hcltech.com/blogs/factories-future

https://blog.huawei.com/2018/08/31/smart-manufacturing-what-are-the-challenges/

https://www.futurismtechnologies.com/blog/the-need-and-challenges-of-smart-factory-solutions/

What's your view?

About the Author

Jigyasa Arora is a Delivery Lead within Private Equity practice at Acuity Knowledge Partners, and has about 9 years of experience in analyzing and executing research projects. She is proficient in different aspect of research such as research planning, secondary research using public as well as paid source. Her previous experience includes tenure with one of the Big Fours, where she assisted in business research, development of the search strategy, including researching potential target industries and construction of company target lists across different industries and geographies.

Like the way we think?

Next time we post something new, we'll send it to your inbox